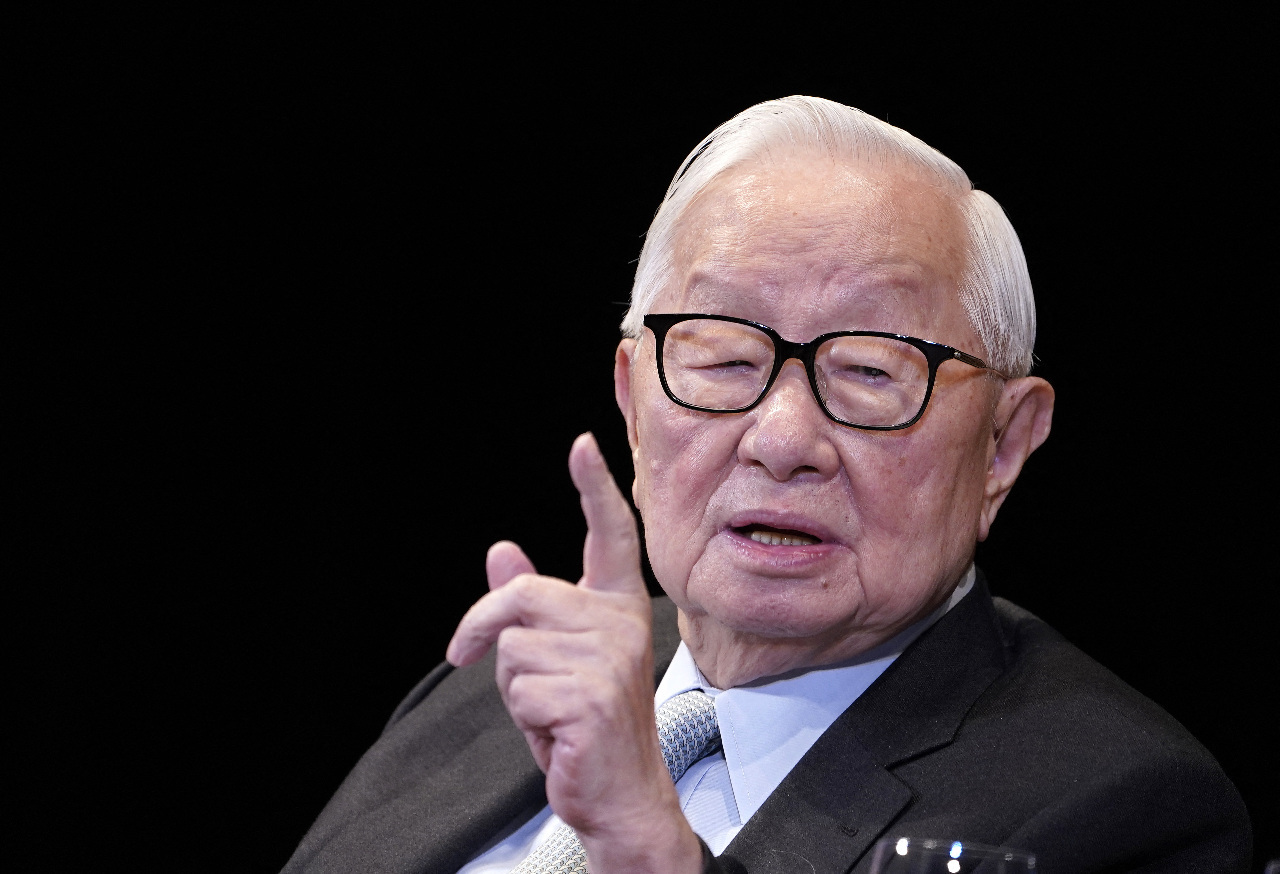

In 2011, during a pivotal moment in the tech world, Apple CEO Tim Cook expressed his disappointment with Intel's chip manufacturing capabilities, a conversation that would shape the future of Apple's processor supply chain. According to Dr. Morris Chang, the founder of Taiwan Semiconductor Manufacturing Company (TSMC), this candid discussion occurred during a meeting that would later prove to be one of the most influential in the semiconductor industry.

The backdrop of this conversation was Apple’s search for a reliable chip manufacturer for its products. At the time, Apple had begun shifting its mobile devices, like the iPhone, to rely on more specialized processors rather than just Intel chips. This was an early sign of Apple’s intent to gain full control over the design and production of its processors. Intel had long been the dominant supplier for personal computers, but its ability to handle Apple's growing chip demands was called into question.

Dr. Chang’s autobiography reveals that Apple’s Chief Operating Officer, Jeff Williams, played a crucial role in setting up the meeting between Cook and Chang. This meeting followed a crucial decision Apple had to make: whether to continue working with Intel or to pursue an alternative partner. At the time, Intel was competing with TSMC for Apple's chip manufacturing business, and the stakes were high.

During their dinner at Apple's headquarters, Cook shared his reservations about Intel's capabilities as an original equipment manufacturer (OEM). While he didn’t go into specific details regarding Intel's cost structure or production yields, Cook made it clear that Intel was not up to par with the expectations Apple had for its chip suppliers. This frank critique led to a two-month pause in negotiations between Apple and TSMC as Apple reconsidered its options.

This conversation turned out to be a pivotal moment for Apple, as it led to the company increasingly relying on TSMC for its chip production. TSMC, with its cutting-edge manufacturing technology, became Apple's exclusive chip supplier, producing the processors that power devices like the iPhone, MacBook, and iPad. While Apple had initially experimented with a dual-sourcing strategy, quality issues with Samsung Foundry’s products pushed Apple to place its full trust in TSMC.

TSMC’s growing partnership with Apple allowed the tech giant to take control over both the design and manufacturing of its chips, ensuring access to the latest innovations in chip production. This move also allowed Apple to avoid relying on Intel's traditional processor architecture, which had become a bottleneck for the company as it sought to innovate at a faster pace.

The A8 chip, which powered the iPhone 6 and was built using a 22-nanometer process, marked a significant shift. It was the first chip designed by Apple to rely on both Samsung and TSMC for manufacturing. Over time, TSMC gradually took over all of Apple's chip production needs, becoming the undisputed leader in the field.

Dr. Chang's recount of his meeting with Tim Cook underscores a defining moment in the semiconductor industry. Cook’s directness and insight into the limitations of Intel’s capabilities led Apple to establish a crucial partnership with TSMC that continues to shape the mobile and computing landscape today. Through this collaboration, Apple not only gained access to TSMC's advanced manufacturing technology but also redefined the future of its hardware development.

WCCFTECH

Read More

Friday, 20-02-26

Friday, 20-02-26